Mat Hoffman, The Ride of my Life, 2002: With the sport continuing its downward spiral, withering and shrinking, there were hardly any events or competitions left to attend. The thriving scene of the '80s was gone. But freestyle was far from dead -it was just underground. From my perspective, I didn't really have a choice. I needed a bike, I needed contests, I needed a community. In short, I needed to get off my ass and make it happen. The companies that still made freestyle bikes didn't seem particularly committed to, or even interested in freestyle as a sport. They saw it as a number, and with the bike industry sales in decline, that number did not command much respect. In the past, I'd been offered a chance to have my own signature bike on Haro. I should have been stoked, but my 'question everything' mind-set was provoking me to do a lot of soulsearching. If I was going to put my name on a bike, I didn't want it to be at the mercy of bean counters. I didn't want somebody's lackluster bike sale stats to control who I wanted to be. My lifestyle revolved around a sport of self-control, mastering the ability to adapt to weird environments. If there's one thing I knew how to do, it was ride transitions.

I didn't know dick about building Bycicles I just knew how wanted mine to ride. I ransacked my Rolodex, making calls and asking questions of some of the manufacturers in the industry, researching how stuff got built, and how to translate my ideas as a rider into bent and welded steel. I got ahold of Linn Kastan, one of the greats in BMX history. Linn is the guy who basically invented the BMX racing bike. He was in charge of the first awesome BMX bike company, Redline (who also had the first great BMX team). To his credit he had the creation of the first tubular forks, handlebars with a crossbar, and highperformance Flight cranks. It was an honor to have him help show me the ropes. I started planning the way any kid with a dream does by scribbling my frame designs on paper. I went to Linn's house where my crude drawings became intense technical discussions. We tuned the geometry in the drawing and discussed the dilemma of weight versus strength. I wanted a bulletproof bike, but it had to fly. There were incidents in the past where I'd broken three brand-new bikes in one day -and was sick of that crap. I wanted top quality, which meant using American made 4130 aircraft grade chrome-moly tubing, the best money can buy. I was also stoked that it was going to be built in America, which was a rarity for freestyle bikes. A couple of weeks later Linn's machine shop had built me five prototype Condor frames, one for Steve Swope, Rick Thorne, Dave Mirra, Davin Hallford, and me. Our mission was to try and break them. The Condor was good. It was quick, it was stiff, it had clean angles, but more than anything, it was built to last. (rode my prototype frame and fork set for seven months, trying everything in my power to bring it to its knees. The bike held up to flatbottom landings, rooftop drops, handrails, gaps, dirt, street, ditches, extreme weather conditions, name-calling, and giant ramps. I caused my body way more harm than my bike, and the rest of the prototypes held up, too. Midway through the testing phase, I made a couple of minor improvements and declared the design phase done. Time to see if the public would buy them.

Mat Hoffman, The Ride of my Life, 2002: Precision materials and craftsmanship came with a steep price tag, and I found out I couldn't afford to have Linn Kastan's shop do production. Mike Devitt of SE Racing saved the day. Mike was another old school BMX guy, and he'd been through the ups and downs of the industry with another legendary company, SE. Their machine shop could make a limited run of custom frame and fork sets. The condition was, I had to pay for half the batch up front, the other half on delivery "Make me two hundred of these," I told Devitt and sent off the schematic for the Condor with a down payment check for $18,000.

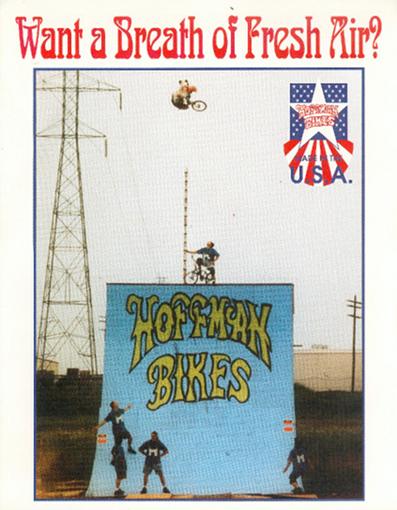

With bikes on the way, I needed employees. Steve didn't even have to think about it -he was in. We set up offices in the Ninja Ramp warehouse, cobbling together desks and chairs from thrift stores. Steve and I both concurred we'd need a computer or we'd be dead in the water. We bought a new Apple II LC, 80 mhz with about eight megs of RAM, which was state -of-the-art 1992 hardware. As we pulled the Mac out of the box, neither one of us knew how to turn the thing on. I called Brad McDonald, publisher of the newly minted Ride magazine, who seemed to have his act together with computers and desktop publishing. Brad gave me a few phone tips, and Adobe Illustrator was installed. I stayed rooted in front of the screen for twenty hours a day, mousing and clicking, and two weeks later the first Hoffman Bikes product catalog was ready to take to Kinkos to get printed. While out in Los Angeles on a shoot for Dirt magazine, Spike snapped photos for the catalog for free (Spike, thanks again). Steve bought an accounting and inventory program, and he embarked on a crash course, teaching himself operational basics in a series of long nights. We were a company.

A couple months later, the UPS guy rolled up with a truckload of boxes and a big fat C.O.D. invoice. The first batch of Hoffman Condor frame and fork sets had arrived. It was a glorious day. Some were already earmarked as giveaways -I gave a few to deserving riders -but the bulk of the shipment was going to dealers. We stacked the bikes right next to the Ninja Ramp, polished them and slapped on the decals, then reboxed our booty and prepped our orders. In the time we'd waited for the payload of frames to arrive from the machine shop, Steve and I had worked the phones and faked our voices to sound older and more confident. We convinced a few shop owners around the country to carry our product line, which was a feat in itself considering the bleak bike market. Because of the manufacturing costs and high-quality materials, by the time the Condor frame and fork sets were hanging on bike shop walls, they cost around $350. At the time, a budget-minded shopper could pick up a generic, entry-level complete bicycle for around $200. But there were ample numbers of hardcore riders out there willing to shell out the clams, and by some miracle, we sold out of our first run of Condors in one month.

This cycle was repeated as fast as we could afford to rebuy another production run and get the machine shop to fabricate the next batch. It took about six months. In my opinion, that was too damn long to wait for a bike. I felt orders slipping away; I knew if I were a kid with a wad of cash in my pocket, I'd have a hard time waiting half a year to get a new bike. Another problem we had involved juggling the money -we'd bring in cash from doing demos or touring with the Sprocket Jockeys, but the semi literally burned cash every time we turned the key in the ignition. In addition, although most of our bike shop accounts were pretty honest, there were a few rubber check writers out there. Accumulating the down payment dough to set SE's machine shop into motion on our bikes involved a substantial amount of scraping, saving, truth-bending, and creative financing. A bank loan was out of the question -they wouldn't give me the time of day. I was a dropout with an eighth-grade education and no manufacturing experience. Furthering my anxiety, I had a feeling sometimes the SE guys would stop in the middle of a run and work on another company's production jobs. Delays eat into timelines, and it was frustrating Steve and I knew from the interest we'd had with our bike shop accounts, we could sell everything we could make We just had to supply the demand, pronto. My solution to this economic mayhem: Dig the hole even deeper.

Ride BMX UK april 1994: When Matt Hoffman started his own bike company a couple years ago, everyone and their senile great aunt wanted one of his frames. There was no doubt that Matt, with his years of practically unbeaten contest victories and a reputation on a par with Evil Knievil, would be able to create a damn good bike befitting his signature. He certainly did - decent wheelbase, clean lines, integral seatclamp, AD's, large oval tubing, nice n' strong, and even flame graphics. Right off his own bat Matt had created the bike that Haro wouldn't build for him. It was an ideal bike for ramp riders.

MK1 CONDOR FRAME AND FORKS.

Year: 1992

Production Run: 2 x Batches of 150 (inc 50 completes)

Made by: SE Racing

Weight: Frame 5lbs 8oz, Forks 2lbs 4oz

Colours: Chrome or Blue

Kevin Jones designed a signature flatland frame for Hoffman Bike. The Big Daddy.

condor96, www.radbmx.co.uk, february 2010: Late summer/early fall 92, Mat Hoffman runs the idea across Kevin Jones about a signature frameset and a spot on the team. The deal with Jones on the team is there is no deal, meaning he doesnt do the Sprocket Jockey shows, B.S. contests or even be in Hoffman bikes vid. Kevin designs the framesets and gets a royalty off everyone sold. Kevin Jones and Brett Downs design and draw up the bluprint for the big daddy on Kevin's parents pool table. The design was 50/50. Blueprints get to Hoffman by november 1992. Early 1993, Kevin is first riding around and spotted on his black prototype Big Daddy. Summer of 1993, production frames are available in chrome or green. Made by SE (only one batch of SE made Big Daddies were built), no serial numbers, 3/16th rear dropouts, two cable guides, the "marlboro" box bb wishbone and the coaster brake bracket on the bottom of the chainstays. Early 94,right before Hoffman brings bike production in house, some leftover SE made bikes (both the big daddy and condor) got the new style decals. I think thats where the misconception on SE vs ramp room made Big Daddies came from. May 94, production starts in house in the ramp room. The Big Daddies were a primary focus during the summer of 94 as a lot of people wanted to get their hands on one. Very similar to the SE made Big Daddies, rear dropouts got upsized to 1/4 inch, along with a B4xxxx serial number on the inside of the left dropout (even tho this gen ran until mid 95, they still got a B4xxxx serial number), looses a brake cable guide and the coaster brake mount went onto the seatstays instead of the chainstays. Forks got a kink on the leg instead of a curve. Colors for ramp room stuff is almost endless as i've seen loads of different colors. Mid 95, the Big Daddy started getting some updates. I call these the "transition" models. 2 different versions and it was a running changeover that happened fast. This is when they stopped putting serials on the frames and the "marlboro" bb box went away to the rounded wishbone. The earliest of the two didn't have a coaster bracket and it was the last of the earlier decals as the new ones were being phased in. Then right after that the other version of the transition model came out, with the new decals, and the coaster bracket back with the rounded wishbone, but the last of the curved rear dropouts. Early fall 95, the last ramp room version of the Big Daddy comes out, with the straight edge rear dropouts. Mid 1996, ramp room production is shut down and all bikes are now made in Taiwan, started getting serials again starting with a hkf. HB stamped ht gusset,14mm rear dropouts, rounded instead of capped stay ends with a slightly different shape of dropout. Fork legs got a curve instead of the kink. Dropouts were 3/8 axle slots but a slightly different design. 97 product guide is showcasing mid 96 product. Early 97, last version of the Big Daddy. It stays almost the same, serial now starts with a kf, and the forks get a rounded bottom fork leg with the big dropouts with 14mm axle slots. In the mid 97 product guide they are listed as the classic series, a limited re-release of 96 models (even tho they are slightly different from 96s)

Ride BMX UK april 1994: The Condor was an ideal bike for ramp riders - only thing was, it pretty much sucked for flatland. Matt and the OK crew decided that they needed a shorter more responsive frame - and who better to ask to design such a bike than the Lord of Flatland himself, Kevin Jones. The Hoffman Big Daddy has some unique design features which look quite useful. From front to back, the headtube is a one-thickness tube all the way down, good deal. The next thing you notice is the gussett deal: the downtube is welded up pretty high on the headtube and connects with the toptube, and between the downtube and the headtube is a nicely formed plate gussett which finishes off the junction very nicely indeed. It looks top dollar for sure. Toptube is a round 1 1/2 inch tube, whilst the downtube is a meatier oval tube which is 1 11/16ths inch by 1 7/16ths inch - beefy indeed. On the top of the downtube are 2 cable guides directing the brake cable into a thru-the-seattube guide to an AD990 brake on the chainstays. A proven set-up. The platform is formed, like the others, from extended 3/4 inch OD seatstays. The toptube is pierced by the regular [7/8ths inch OD seatpost size] seattube and capped off at end at an angle, and there is a square 3/4 inch box-section tube finishing off the platform. There's also a 3/4 inch box-section tube for the brake bridge, but you're not actually going to put a brake on there are you? The chainstay set-up is similar to the Bully Piston, with a wishbone junction at the BB shell - only this time the wishbone is box-section tube a whopping 2 inches wide by 1 inch high. The wishbone is capped by a curved end around the tyre, and it looks super-clean - it sets the frame apart from the others and provides a very strong junction at the same time. Ends of the stays are capped. Dropouts are 3/16ths inch [4mm] thick - future Big Daddy's may go up to 1/4 inch thick, which would be a welcome change. Anyhow, the dropouts have a smooth shape, and they're welded both sides. Coaster brake users will note the bracket welded onto the chainstays. You have the choice of either fine chrome plate or green paint with this frameset. Graphics have received mixed response - flowers, hippy typeface, purple/ orange/yellow colours. They do look pretty cool though. All in all, this is nothing but a high quality frameset. Welding and finish throughout is top notch - after all, it is fabricated by SE who have been making BMX frames since 1735, and it sports some unique design features which are more than cosmetic, they really do work. Kevin has undoubtedly created a damn great frameset, one which won't be limited to flatland either Dave Mirra rode one for half a year on vert and street for example - it's just a shorter, more responsive and well designed frame. But what about the damage? A green Big Daddy goes for £345, while you're going to have to write a cheque out for £360 if you want a chrome one. A hundred quid more than the S&M HAF but basically there's more to it.

Brett Downs, www.global-flat.com, december 2006: Kevin Jones and I drew up the Big Daddy on his parent’s pool table. The design was pretty much 50/50. I wanted to make a few updated versions and though Kevin said he didn't mind, some other issues come up which prevented it. I have one built up and about 3 more. For those of you that would love an updated Big Daddy all I can say is it could happen ?

MK2 CONDOR.

The Condor frameset has been redisigned for '93 and now features 1/4inch thick dropouts and the head angle has been steepened to 74 degrees.

SUPERFORKS.

Stem/fork combo.

BMX Plus! may 1993: After breaking and bending virtually every stem and fork on the market, Matt Hoffman and Chad Herrington have come up with a revolutionary new design that may be indestructible. Since forks always seem to bend at the steerer tube, they have added an extra piece of metal running the length of the tube, which acts as an I-beam inside for added strength. The tube is also about 2-1 /4 inches longer than normal forks. The aluminum stem is then connected to the top of the steerer tube via a set of Allen bolts. This way there is no stem shaft to get tweaked or come loose. This stem/fork combination is currently going through Kiss of Death testing by Chad as well as Davin "Psycho" Halford and they have had no problems so far. This combo should be available in mid-April (chrome forks with either aluminum or "velvet paisley" colored stem (and will cost about the same as a regular stem and forks.

BUILDING IN-HOUSE.

Mat Hoffman, The Ride of my Life, 2002: I went to the Small Business Administration (SBA) and met a lady named Susan Urbach. I expected her to give the "you want to do what?" corporate laugh, but (thought I'd ask her advice about getting a manufacturing facility set up. She told me I needed a business plan, gave me some books, and told me how to put one together for her. I studied the materials, figured out what a business plan meant, and submitted mine to the SBA. It ended up securing us a $40,000 loan to get our operation up and running. We began checking out just how to buy all the machinery needed to start building bikes. Y'alI want to start a machine shop, eh?" clucked the guy from the local vo-tech center "How much money you got?" He sounded skeptical, eyeing our long hair and young faces Steve and I relayed the good news, that we had forty grand. The guy, whom we'd come to for advice as a shop foreman, said there was no way to get all the equipment needed to cut, grind, weld, bend, drill, mill, and polish metal for forty. He said it was going to take two hundred and fifty grand, and that was for a no-frills machine shop. He chuckled again and suggested we come back when I'd saved up for another few years. I told him we had forty, so we'd just have to make that work. We thanked him for his time and bought a newspaper that contained classified ads for industrial equipment. The critical step in our grand scheme was to lure a seasoned shop foreman to help us. There was a guy who fit the bill named Gack. He was from California and had training and technical skills in bike building Gack was an accomplished rider, which was the main bonus as I looked over his résumé. We lured him out to Oklahoma, and with his help we sourced the tools and raw materials for our products. Through persistence and wild deal-making, we'd found all the machines we'd need to turn tubing into gold. The only machine we had to improvise on was the one that bent round tubing into an ovalized shape for the down tubes of our frames. The real version of the machine was tens of thousands of dollars. Steve, Gack, and I figured out how to get similar results using two flat steel plates and a carjack, carefully smashing the tubing until it looked oval. It was rigged to duplicate the same shape-we may have been sketchy, but dammit, we were consistent.

Chad Herrington'Condor with Superforks and Graveyard bars.

Building our bikes in-house didn't solve the money-juggling problems; instead, we'd compounded the insanity. There were twenty-five full-time employees on payroll, plus rent, utilities, raw materials, shipping costs, and forklifts. The monthly overhead was gnarly. Our accounting books just didn't balance, and we were living shipment to shipment. We'd already maxed out our SBA loan, but we needed extra cash to grow the business I figured out a way to approve ourselves for a high-interest loan. We stopped paying taxes for a few months. I didn't like bending the law, but it was either skip the taxes or shut down the business. We used the money we were supposed to give to the taxman to buy more tubing and materials, to hire more people, and to generate more income. I knew I'd have to square up with the IRS eventually, but I never would've guessed they made house calls. One afternoon the IRS agents showed up with guns and badges and demanded to see the company's records. Immediately. After an audit, the IRS informed us we were fined $18,000 in back taxes and penalties. By the time the bill was due, we'd made just enough profit to pay it off. We squeaked through a crucial fiscal year Profit was an elusive leprechaun, and the little bastard seemed to be very afraid of bike riders.

MK3 CONDOR.

condor96, www.radbmx.co.uk, october 2008: Sometime 94-early mid 95. Basiclly same as a mk2 93 but no rear peg mounts and has the flame decals (red, green or purple) and i've only seen in black or chrome.

MK3.5 CONDOR.

condor96, www.radbmx.co.uk, october 2008: Mid 95-late 95 95/96 product guide. The condor gets a overhaul. Big curved wraparound ht gusset, chainstays get a big wishbone and the dropouts are revised with no triangle cutout, big hub protection and 3/8 axle slots. Front dropouts got slightly bigger with much bigger pegboss (1 1/8th inch) by welding another bigger cap over the earlier smaller pegbosses. I've seen in chrome, black, and a flat plum purple with silver decals. I've seen one and it looked sweet.

LOVE HANDLEBARS.

Six piece bars featuring huge tubing for the main structure with the 7/8ths tubing for grips and levers clamped into the top part.

LOW DRAG BARS.

Smaller version of the Patriot bars.

TAJ FRAME.

The TAJ (Totally Awesome Jumper) is a new jumping frame designed by Taj Mihelich.

THE EGG.

Breaking into the mass market with a new 'budget' complete bike, Hoffman has brought out The Egg, this entry level bike comes with a Taiwan-made 4130 cromo Condor-like frame.

Love Handles.

Hoffman Bikes made a BMX Racing bike called the Flash.

MK4 CONDOR.

condor96, www.radbmx.co.uk, october 2008: early 96-late 96 later flame decals. rear dropouts are made slightly smaller with 14mm slots. gusset is more flat shaped with straight edges and hb logo. fork legs are changed from the kinked ones to a more curve. legs are upsized and pegboss is a one piece right at the bottom of the leg. dropout is revised still with 3/8th slots and the peg boss is still 1 1/8th inch. some decals on 96/97 have made in usa on them, others do not. its hit or miss. 96s serials start with some form of hkf. hkfd,hkfc etc

ive seen in chrome or black. but ive heard they also did some in a dark green.

MK4.5 CONDOR.

condor96, www.radbmx.co.uk, october 2008: late 96-early mid 97. At a glace almost identical to 96s. Chain and seatstay are kinked in different spots differently, ht gusset got a little tiny bit bigger, little more curved with a curved front where it meets the ht. the rear end got shorter and the top tube got longer. Forks got a way bigger dropout that extends past the peg boss and now with 14mm axle slot. peg bosses grew to 1 1/4 inch and got a bit thicker again. Last of the one inch ht/forks and flame decals. Serials start with a kf.

Hoffman Bikes is coming out with a new entry-level bike that is going to be called The George. Why ? Because it's so fat -just like Matt's cat of the same name.

EP FLATLAND FRAME.

The EP flatland bike designed by Kris Gack, Leif Valin and Matt Gibson.

Ride BMX UK august 1997: Hoffman Bikes base replaced the excellent Big Daddy frame with an all-new flatland frame, the EP. The EP claims to be the shortest bike to date, and with a wheelbase of just 33 5/8 to 35 1/8 it could well be. A sharp 75° headangle keeps it tight, the back end is short and features adjustable AD brake logs to fully dial in the rear braking. The EP is beautifully well made, oval stays, end it's also 1.1/8" oversize. The EP frame, fork, and bolt on AD logs comes as a kit, and it sells for a reasonable £335. Awesome.

Leif Valin, Looking Glass #2, 2003: The Hoffman e.p. was shorter than the previous flatland frame (rear and length) so it was aptly named e.p. like an e.p. record, shorter, fewer songs. The first headtube sticker on the e.p. was a record.

Kris Gack, product engineer extraordinaire, is leaving Hoffman Bikes and heading to Northern California.

Ride BMX UK october 1997: HOFFMAN BIKES will still make the TAJ frame one of their best selling models but it will apparently be called the Bike Formally Known As Taj, and it will carry a small symbol on the toptube. Taj himself is still obviously riding, but as a complete free agent doing just what he wants.

MK5 CONDOR.

condor96, www.radbmx.co.uk, october 2008: mid late 97-early 99 sometime. Released mid 97. Different blue decals, chainstays curved in alot and gusset went back to the 96 style but same diementions, as the early 97. first of the 1 1/8th oversized. forks got redone again with 3/8ths slots and pegbosses back up the leg a bit. fork legs slightly bigger. Could get in chrome or flat black and mid 98 they came out with a candy red. Serials start with a cibc.

Hoffman Bikes new Rooftop&Butcher designed frame "The Deebo" is finished. It's named after Matt's new puppy.

MK6 CONDOR.

condor96, www.radbmx.co.uk, october 2008: late 98/early 99-about mid 2000. I've seen in chrome,white,and flat black. ht gusset got way longer going down the down tube. its also when the condor started getting the bigger seat tubes(they got even bigger after this gen). The 99 and later models started getting broke down into three different groups. the star series (2 pc bars,1pc cranks with the less expensive sprocket.) the team series (love handles,1 pc cranks) and the pro team series (love handles and primo powerbite 3pc cranks).

More than 30.000 BMX Hoffman Bikes were sold in 2001.

Seth Kimborough's signature frame.

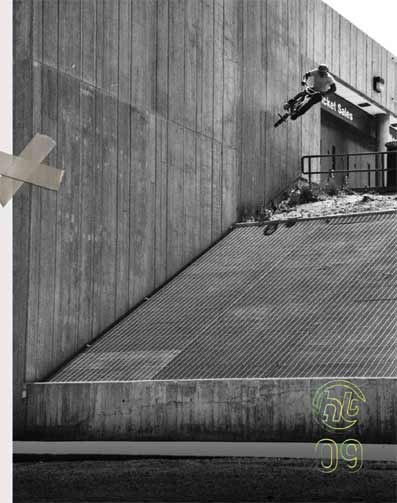

digbmx.com, august 2007: Everything, from the completes way on down to the components has been refined, and there's a few new additions to the HB frame line (including the Mantra frame, pictured below, featuring 100% 4130 Cromo, Single and Double-Butted Tubing, TT: 20.5" • 20.85" • 21" HT:74.5° SM:71° CS:13.7 BB:11.4”, Removable Brake Mounts and Cable Guides, Mid BB, Integrated Headtube w/Removable Detangler Tabs, Colors: Steel Blue, Lotus). Plus that, the new graphics compliment the line really well.

B-RAD FRAME.

Brian Tunney, espn.go.com, may 2009: Hoffman Bikes new B-Rad Brad Simms signature frame is now available. The B-Rad frame is constructed of a combination of single and double butted 4130 cr-mo, with an integrated down tube gusset, tapped top tube, seat and chain stays, 5mm internally machined and heat-treated dropouts, removable brake mounts and removable detangler tabs. The B-Rad frame is available in three top tube sizes (20.5", 20.875" and 21.1") with a 74.5 degree head tube angle, 13.66" chainstays and 11.5" B/B. Weights for the frame vary according to the top tube lengths: (20.5": 4 lbs 9 oz, 20.875": 4 lbs 14 oz and 21.1": 5 lbs 1 oz.) This frame will not necessarily increase the number of stamps on your passport, guarantee the ability to bench press 300 lbs or make you the apple of every Eastern European girl's eye, but it's a Hoffman and if it's not breaking under the wrath of Brad, then it should work for just about anyone.

Press release, february 2014: Founder of Hoffman Bikes and one of the world’s best BMX Freestyle riders Mat Hoffman, announced today a new licensing partnership between Hoffman Bikes and Pacific Cycle to expand Hoffman’s exposure and distribution globally with the high quality standards for which the brand is know for. “It’s very exciting to build great bikes with Pacific Cycle’s awesome resources and super knowledgeable team,” said Hoffman. “The Hoffman brand now has the opportunity to reach a new generation of riders.” Hoffman is set to release new bikes that will be sold at Independent Bike Dealers (IBDs) domestically in the U.S. and internationally in 2014. The brand will continue to provide bikes for athletes of all levels.

Mat Hoffman, The Ride of my Life, 2002: The coolest aspect of building bikes is being able to enjoy them. When I was growing up and riding for other companies, it was frustrating to submit suggestions to my sponsor about product development or marketing and have them nod politely, with no intention of acting on my input. If my forks broke and left me in a coma for a day I had to deal with it as an unavoidable occupational hazard" rather than a design flaw. With my name on the down tube, I made it a personal commitment to be a control freak about every facet of Hoffman Bikes. Steve and I put together the best team we could hire. Part of it was for selfish reasons -so we'd have awesome guys to ride with- but it was also for strategic reasons. The best team meant we would also be getting the best input and could channel that brainpower and creativity into top-notch products. When our rider Kevin Jones came up with a new head tube gusset design, we not only listened but acted. Gack came up with the idea for oversized axles, and our core R&D team (Steve, Gack, Chad Herrington, and me) came up with the Super Fork. Today, all manufacturers' high-end bikes come with similar head tube gussets, oversized axles, and forks that employ the same design as the Super Fork. An entirely new set of industry standards were created by rider input.

Early on, we could barely afford to pay for products or get our team to events, let alone put our riders on lucrative salaries. At first, the guys on my team got a good bike, a free place to stay If they were in Oklahoma City, and a black leather jacket with Hoffman Bikes painted on the back When we lured Dave Mirra onto the team, we couldn't even afford to get him a new jacket, so I gave him my leather from the Swatch Impact tour and had it repainted with an HB logo. The black jackets were our armor against the corporate mentality.

When Jay Miron started riding for us, he abandoned his Canadian homeland and moved to Oklahoma City. We rode together every day, pushing one another and progressing He pitched in around the offices, doing everything from working the phones to helping ship orders. Kevin Robinson was another kid who was one hundred percent committed. He relocated from the East Coast to Oklahoma City for a year, just to help out with our cause. That kind of teamwork made our operation more than a team-it was a family. Over the years, Hoffman Bikes was fortunate enough to expand and got the honor of sponsoring a ridiculously talented roster of ams and pros, such as Taj Mihelich Simon Tabron, Ruben Alcantara, Evel Knievel, Rooftop Escamilla, Jay Mired, Dave Mirra, Psycho Hallford, Kevin Robinson, Butcher Kowalski, Day Smith, Rick Thorne, Chad Kagy, Seth Kimbrough, Kevin Jones, Chase Gouin, Pat Miller, Jimmy Walker, Mad Jon Taylor, Rob Sigaty, Brian Tunney, Leif Valin, Achim Kujawski, Daniel Randall, Eduardo "The Fly' Terreros, and many others.

Davin Halford 1993 - ....

Chad Herrington 1992 - ....

Mat Hoffman 1992 - ....

Chad Kagy 1998 - signature bike in 2002 - jan2003, former Hoffman Bikes rider Chad Kagy is now on Specialized.

Matt Gibson 1999

Chase Gouin spring 1993 - ....

David Halford (psycho)

Mat Hoffman

Seth Kimbrough pro model 2002: instrument frame

Joe Butcher Kowalski december 1996 - autumn 2001 and then riding for FBM

Gerry Galley was touring with the Sprocket Jockeys and riding for Hoffman Bikes in 1994.

Koji Kraft april 2002 - ....

Achim Kujawski 1993 - ....

Kevin Jones 1993 - ....

Taj Mihelich fin 1994 - summer 1997

Dave Mirra 1992 - 1994

Jay Miron spring 1993 - may 1995 and then riding for Schwinn.

Anthony Napolitan .... - Mat Hoffman, august 2010: After 7 years with the Hoffman team, Anthony Napolitan has decided to part ways and explore other opportunities. "Anthony made me proud watching all he contributed to our sport riding one of my bikes. Thanks for the radness Anthony! Enjoy the ride!"

Mark Chuck D Owen 1993 - ....

Kevin Robinson 1998 - ....

Steve Swope 1992 - ....

Day Smith end of 1993 - ....

Chris Stauffer .... - march 2000 then riding for Federal

Simon Tabron 1992 - ....

Rick Thorne 1992 - february 2002 then riding for Free Agent.

Leif Valin 1994 - september 2001 Leif has left Hoffman to design products for Eastern Bikes.

Jimmy Walker april 2002 - ....